SILGA – Oil Sands Tour

I was offered an opportunity to see the Alberta Oil Sands complex situated around the Fort McMurray area in northeastern Alberta. The Canadian Association of Petroleum Producers (CAPP) arranged a tour of both the Suncor and MEG sites. CAPP arranged and paid for the flight and meals for SILGA (Southern Interior Local Government Association) representatives that wished to get a better understanding of this multi-billion dollar Canadian endeavour. The size and scope of this operation can only be described as incredible.

These huge trucks are what moves the oil sand material from the mining extraction sites to the processing plant. This is where the material is crushed and heat in the form of steam is used to “get the oil out of the sand.”

A history of how the size of trucks has increased as the Oil Sands has expanded trough out the years.

There was literally kilometer after kilometer of these large diameter pipes moving both steam and the extracted bitumen throughout the complex.

I had to get a shot of the plane that the Canadian Association of Petroleum Producers (C.A.P.P.) supplied for our tour.

These are the platforms at the MEG site further north where the steam is injected (300 meters in this case) and the liquified bitchem is recovered and piped for further processing and storage. These reserves are recovered in place, or in situ.

These are gigantic boilers where the steam used in the extraction process is produced.

Below is the Control Room at Suncor where the whole process is managed and monitored.

Both these sites were state of the art in what they were doing and safety was stressed as the primary concern for both the workers and the environment. I was provided with more information on the site and the processes used to provide Canada with energy for our domestic needs and export to the world. Is it the right thing to be doing? That answer can only come from yourself and how you interpret the information available to you to make that decision. Please make your decision based upon the facts and history of this process that has been evolving with an innovative Canadian can do attitude and technology since 1967.

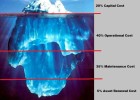

80% of oil sands reserves are too deep to be mined. These reserves are recovered in place, or in situ, by drilling wells. Drilling (in situ) methods create minimal land disturbance and do not require tailings ponds. Advanced technology is used to inject steam, combustion or other sources of heat into the reservoir to warm the bitumen so it can be pumped to the surface through recovery wells.

My only wish from this tour would have been more time to get a little closer to both the extraction/processing side as well as the reclamation part of the process.

Some of the documents provided to me are:

CAPP Booklet – The Facts on Oil Sands 2015